6 Questions with Gilbert Lares, Bentley’s Digital Studio Manager

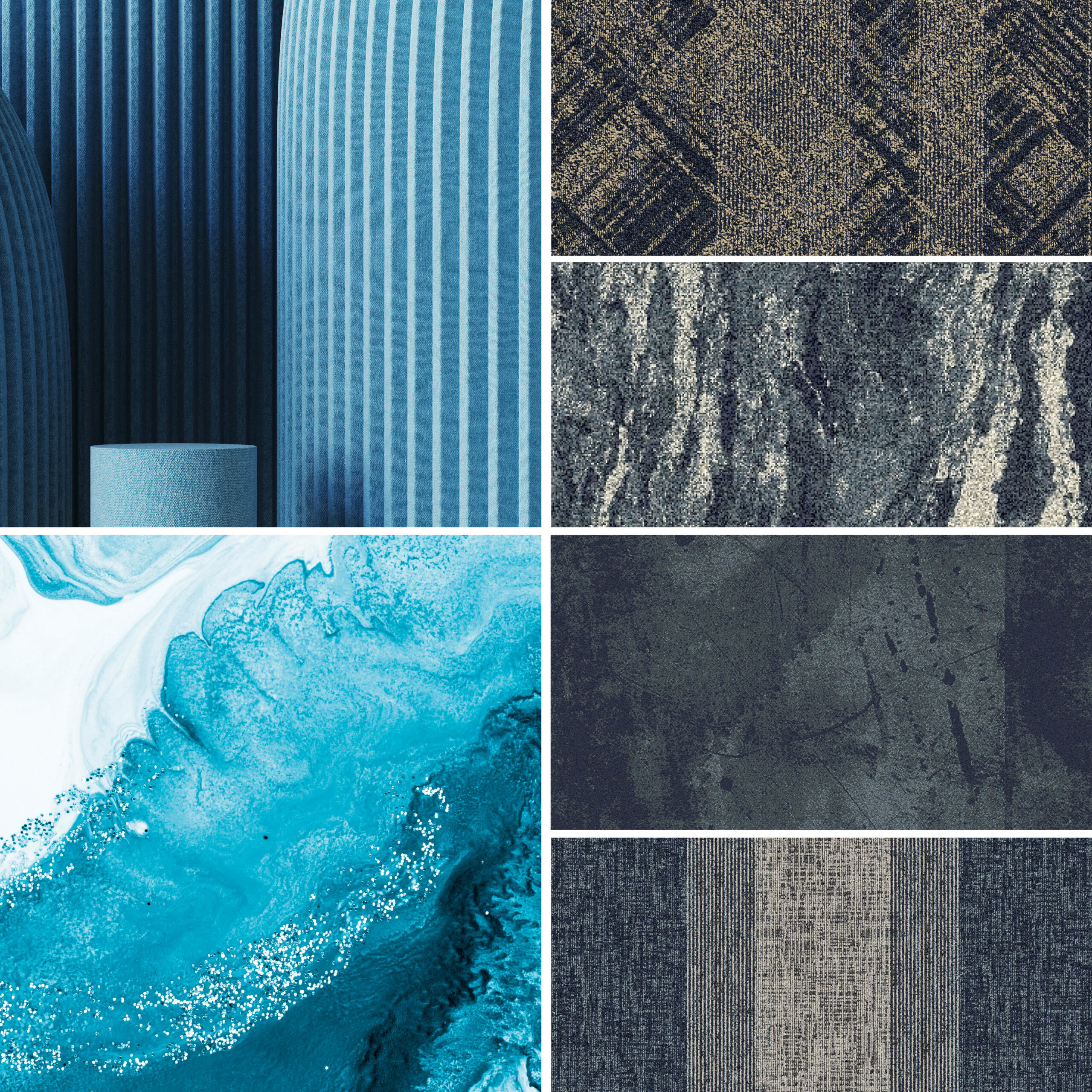

The world around us is increasingly digital – and the world of commercial flooring is no exception. Bentley’s Digital Design Studio incorporates technology into the design and specification process, helping designers and specifiers visualize our carpet and LVT in their spaces. From installation methods to color schemes, floor plans and 3D room scenes, digital renderings and print simulations, our Studio makes digital feel real. And we save time, money, and other precious resources in the process.

How, you ask? Gilbert Lares, a 27-year Bentley veteran and manager of Bentley’s Digital Design Studio, offers his insights. Read on.

How does Bentley’s design studio use digital technology, and what role does this technology play in creating Bentley carpets in an eco-friendly way?

The Bentley Mills Digital Studio takes great pride in our ability to use software to replicate carpet.

When a new product launches, our team in the Digital Studio incorporates the new design into our software and use virtual tufting machines to create printed carpet simulations. Using this technology presented a few challenges at first. Primarily, customers who regularly received traditional yarn-fiber samples were not prepared for the change. However, once they understood the environmental impact of the new technology, excitement grew. Rather than tufting 20-40 traditional yarn-fiber samples as we typically would, Bentley now produces 20-40 digital simulations or recyclable printed simulations. Once designers narrow these simulations down to a few finalists, Bentley can tuft those designs, saving significant resources.

What makes Bentley unique – and why does it matter for designers?

Bentley cares about quality, and that all starts with following procedures and adhering to the highest of standards. Everyone here is committed to sustainability; we build our products to last.

We also have an intense focus on segment specification. Our customers trust us because we make it a priority to ensure the right designs and products are used for the right segments. After all, different segments have different needs. We work closely with designers across all segments to achieve their unique goals.

Perhaps most importantly, Bentley embraces the future, which is centered around technology and sustainability. We’ve rapidly expanded our digital technology use to save material resources and time upfront while ensuring we’re delivering to the exact, and evolving, needs of our customers.

What affect has pandemic had on Bentley’s Digital Studio?

Since the pandemic began, the studio’s activity has increased by 10% due to heightened demand for socially separated designs. A couple of months ago, the studio started receiving daily requests for products with a social distancing component incorporated into the design. For example, our team is currently working on floor plans and room scenes for an entire library with social distance wayfinding incorporated into every flooring aspect. Customers are now looking for projects with cubicles distanced further apart, two-laned corridors with highly contrasting colors, and other designs that create boundaries between people.

This high demand for wayfinding products led to our team rethinking how we design products. We want to make sure that the wayfinding designs we create for our clients aren’t just “Covid-customs” but have a more timeless, beautiful appeal that will outlast the pandemic.

How has your role at Bentley evolved over the years?

Bentley Mills has been my school. I began my career here working with tufting machines, becoming very familiar with the extensive process of designing product. From there, I moved into the specification department and then to design.

Through hard work and guidance from the people around me, I climbed the ladder to a managerial role in both the digital studio and specification department. I would never have been able to get to this point without Bentley Mills opening new doors for me, and I’m so grateful that they did. Through learning from my coworkers, I was able to find a craft that I love and make a career out of it.

What is your favorite part of your job?

The best part of my job is easily the ability to unleash my creativity on a day-to-day basis.

I love working with customers throughout the design process – watching a design that started as an idea turn into an immersive experience. There is an incredible feeling associated with a finished product, knowing that my creative ideas and process help designers achieve their vision. It’s truly gratifying.

What do you love most about working in Los Angeles?

First and foremost, the weather is always beautiful. More importantly, the people that I work with genuinely make the job an even more fulfilling experience. Being able to surround myself with some of the industry’s top minds helps me become a better and more creative worker. At Bentley, everybody is willing to collaborate and support one another in meaningful ways.

Everyone on our team brings something unique and imperative to the table, and at the end of the day, there is a shared vision. We all have the same goal: working together to create something beautiful that will serve an essential purpose.